High Cekap PET Granulating Mesin

Ciri

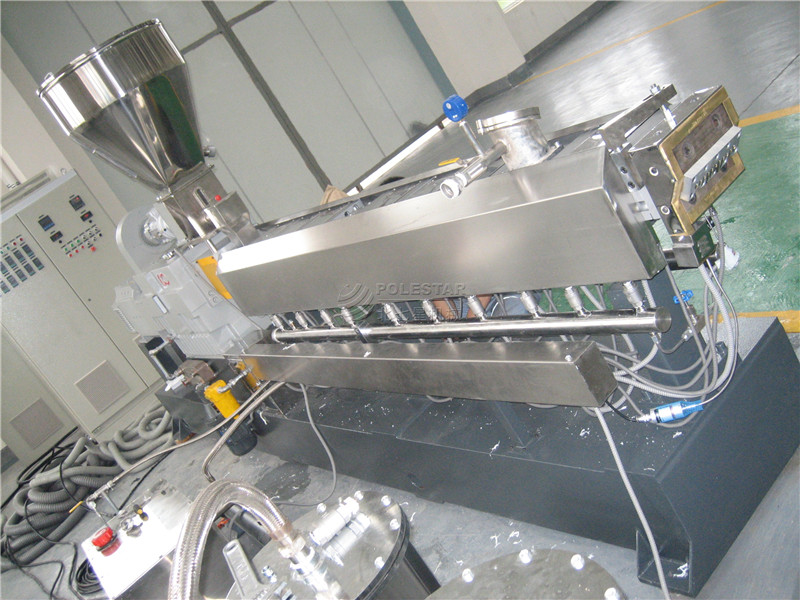

The pelletizer pepet utamana diwangun ku parabot handap: extruder, layar changer hidrolik, strand motong kapang, cooling conveyor, dryer, cutter, kipas niupan sistem (dahar jeung drying sistem), jsb Paké paralel kembar screw extruder boga kontrol hawa akurat. , output luhur kalawan konsumsi kakuatan handap.

Aplikasi

Mesin pelletizing piaraan ieu dipaké pikeun nyieun pepet flakes plastik kana pellet atanapi granule.Twin screw extruder daur ulang & sistem pelletizing anu dilarapkeun kana bahan runtah, nu perlu kinerja processing tinggi lebur, volatilization, nyaring jsb.

Aliran Prosés

Screw feeder (PILIHAN)→ Force feeder→ Parallel twin screw extruder → Hydraulic filter exchanger→ Mould head → water cooling tank → Plastik cutter standar → Réngsé bungkusan produk.

Katerangan lengkep ngeunaan Unggal Item

1. Screw Feeder: nepikeun scraps Plastik kana mesin utama.

2. Force feeder: feed bahan pikeun extruder kalawan speed dirancang, laju bisa disaluyukeun.

3. Paralel kembar screw extruder: plasticizing bahan jeung gas nyapekeun.

4.-speed tinggi Net exchanging Sistim na paeh-sirah: filter impurity bahan, sangkan produksi leuwih stabil.

5. Tangki cai: niiskeun mie pepet.

6. palastik cutter baku: motong mie pepet kana granuels.

Kaunggulan Kompetitif

1. kontrol PLC otomatis

2. Kalawan kadali hawa individu

3. Operasi merenah & kinerja Stabil

4. Kacida efisien, panyalindungan lingkungan jeung hemat energi

Data Téknis

| Extruder | TSK35 | TSK50 | TSK60 | TSK65 | TSK75 | TSK95 |

| L/D (mm) | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 |

| Laju Max (rpm) | 600 | 500 | 300-500 | 400-500 | 400-500 | 300-400 |

| Daya Motor (kw) | 11-18.5 | 22-37 | 37-55 | 45-75 | 90-160 | 185-250 |

| Daya Pamanas (kw) | 16 | 24 | 30 | 34 | 45 | 60 |

| Kaluaran Maks (kg/h) | 20-80 | 50-200 | 80-300 | 100-350 | 200-500 | 700-1200 |

Kategori produk

Hoyong Tambahkeun Langit kana Desain Anjeun?

Taroskeun kami ayeuna pikeun konsultasi desain.